Research Focus on Prof. Rajendra Bordia

George J. Bishop, III Professor of Materials Science and Engineering, Clemson University

Microstructure control and optimization in ceramics

Professor Rajendra Bordia's research is at the intersection of materials and mechanics and is focused on fundamental and applied studies in the processing and properties of complex ceramics and composite materials and systems for energy, environmental, and extreme environment applications.

In a current project in collaboration with Professor Steve Creager and Professor Ulf Schiller research is focused on the effect of electrode microstructure on accessible energy density, at high charge and discharge rates for Li-ion batteries. Li‐ion batteries, as one of the most advanced rechargeable batteries, have attracted much attention in the past few decades. High specific energy (energy/mass), especially at high discharge rate, is nearly always desirable in battery systems, but it is especially important in batteries for electric vehicles. One approach to realizing high power density is to make thick electrodes. However, the thickness of current generation of electrodes, especially at high charge/discharge rates is limited by the transport of liquid electrolyte in the highly tortuous porous electrodes.

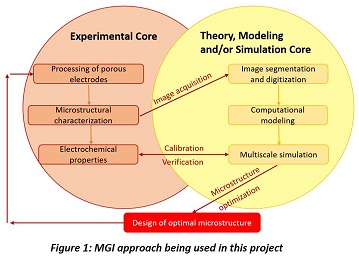

In this project, we are developing an integrated experimental and simulation approach to understand the effect of microstructure on achievable energy density in Li-ion, liquid electrolyte batteries, especially at high charge, discharge rate; and to develop experimentally validated simulation approaches to design optimal microstructures. The focus is on engineered porous microstructures. The MGI approach for this project is illustrated in the graphical abstract.

Experimentally, a range of porous Mo-doped lithium titanate (LTO) electrodes have been fabricated with both random homogeneous (current state-of the-art) porosity and engineered anisotropic hierarchical porosity (using freeze tape casting). The microstructure and the electrochemical performance of both of these classes of porous electrodes have been characterized. It has been clearly shown that the hierarchical anisotropic electrodes have significantly higher specific energy density compared to the electrodes with random homogeneous porosity, especially at fast charge-discharge rates (published in the J. of The Electrochemical Society 164, no. 12 (2017): A2603). All three elements of the experimental part have been completed for the first iteration.

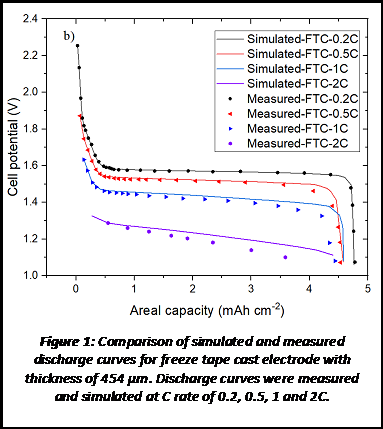

Two-dimensional finite-element simulations of an idealized model for anisotropic hierarchical microstructures have been conducted. The material properties and microstructural parameters for the model have been obtained experimentally. At the meso-scale, the microstructural details have not been considered and the material has been assumed to be an effective medium. It has been shown that the simulations show the correct trends. The simulations also clearly show that the tortuosity in the walls of the anisotropic pores have insignificant effect on electrode performance. The agreement between computational predictions and experimental measurements is excellent, especially for low charge-discharge rates (Figure 1). However, the simulations overestimate the capacity at high charge-discharge rate. All three elements of the simulation core have been completed for the first iteration. The results of this simulation have been published in Journal of Power Sources 474 (2020): 228490. The validation with experimental results has led to the conclusion that the simulation procedure is correct; however, it needs to be conducted on actual microstructures.

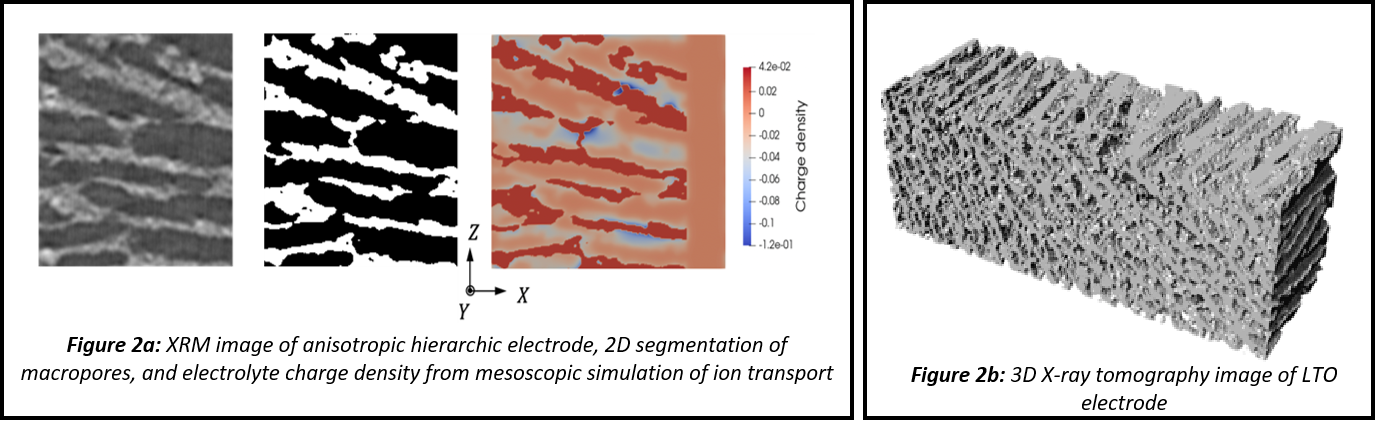

Currently, research is focused on developing two- and three-dimensional models of actual hierarchical microstructures to improve the accuracy of the simulations. For two dimensional segmentations of XRM images, we have performed mesoscale simulations of the charge distribution in the electrolyte (Figure 2a). The simulation model is currently being extended to connect the solution model to the charge transport in the active material. Moreover, three-dimensional digital models of the porous structure are being constructed based on images obtained through experimental characterization of freeze tape cast electrodes (Figure 2b).

Advanced segmentation techniques are expected to enable models that include microstructural details beyond the current effective mesoscale models leading to better match with experimental results. Once the simulations have been validated to reliably predict experimental electrochemical results, the simulations will be used to design the next generation of electrode microstructures for high energy density Li-ion batteries.

October 2020