Anaerobic Membrane Bioreactors as a Next-Generation Technology to Address the Food-Energy-Water Nexus

Scott Husson, Professor, Department of Chemical and Biomolecular Engineering, Clemson University - PI

A Stimulus Research Program Award Supported by the SC EPSCoR Program

(SC EPSCoR SRP Award 18-SR02)

The Research Team:

- Scott Husson, William B. “Bill” Sturgis, ’57 & Martha Elizabeth “Martha Beth” Blackmon Sturgis Annual Distinguished Professor, Department of Chemical and Biomolecular Engineering, Clemson University

- Sudeep Popat, Assistant Professor, Department of Environmental Engineering and Earth Sciences, Clemson University

- David Ladner, Associate Professor, Department of Environmental Engineering and Earth Sciences, Clemson University

- Gary Amy, Dean Distinguished Professor, Department of Environmental Engineering and Earth Sciences, Clemson University

- Nicole Berge, Associate Professor, Department of Civil and Environmental Engineering, University of South Carolina

- Sean Norman, Associate Professor, Department of Environmental Health Sciences, University of South Carolina

- Brannon Andersen, Professor, Department of Earth, Environmental, and Sustainability Sciences, Furman University

- Jessica Furrer, Associate Professor, Department of Computer Science, Physics, and Engineering, Benedict College

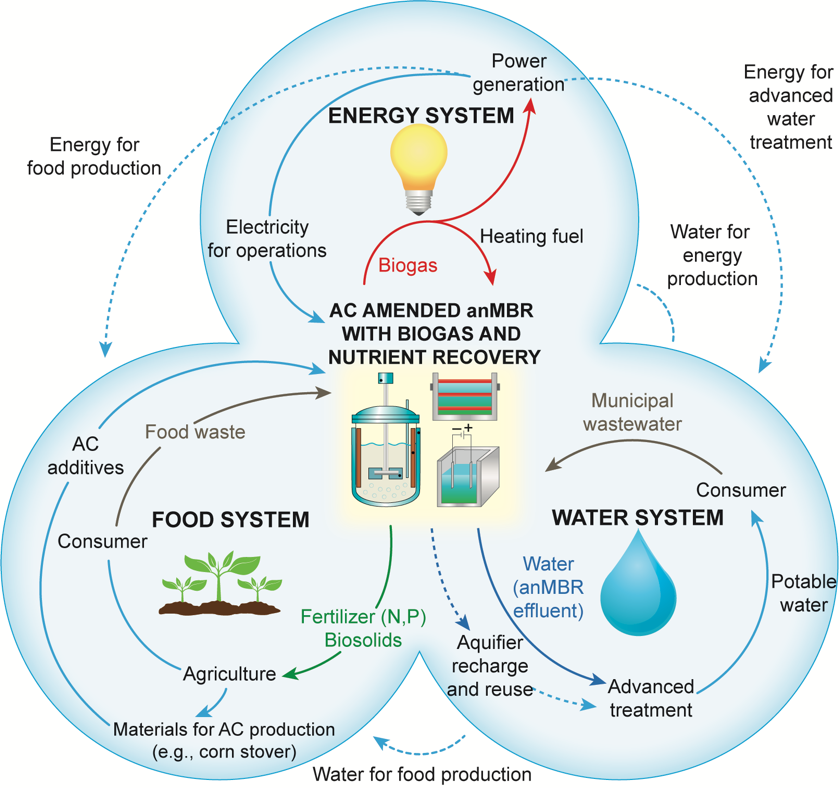

This SC EPSCoR SRP project advocates the anaerobic membrane bioreactor (AnMBR) as a resource factory that lies at the center of a broader network of food, energy, and water systems (Figure 1). Our long-term vision is to establish AnMBRs as a next‐generation municipal wastewater treatment platform for water reuse, energy harvesting, and nutrient recovery, thus addressing key challenges that our society faces at the food-energy-water nexus.

AnMBRs offer the potential for a sustainable approach to municipal wastewater treatment. Firstly, the anaerobic process generates biogas that, if recovered efficiently, could enable energy neutral/positive treatment. Secondly, AnMBR effluent, enriched in nitrogen and phosphorous compared to aerobic processes, can be used for direct crop irrigation, or for the dual purpose of producing reclaimed water and recovering nutrients for food production. Thirdly, AnMBRs can be part of a treatment train for drinking water production, while generating lower volumes of waste sludge. The waste sludge that is generated can be processed further to produce high-value chemicals, recover nutrients, or be used as soil conditioner for agriculture. This SRP project is providing a deeper overall understanding of AnMBR technology in the context of municipal wastewater treatment for resource recovery, which is needed to fully realize the benefits of AnMBRs.

|

|

Figure 1. Anaerobic membrane bioreactor resource factory connecting a broader network of food-energy-water systems. |

Dr. Scott Husson, William B. “Bill” Sturgis, ’57 & Martha Elizabeth “Martha Beth” Blackmon Sturgis Distinguished Professor in Chemical & Biomolecular Engineering at Clemson University leads the project team of researchers from Clemson University (Dr. Sudeep Popat, Dr. David Ladner, Dr. Gary Amy), University of South Carolina (Dr. Nicole Berge, Dr. Sean Norman), Furman University (Dr. Brannon Andersen), and Benedict College (Dr. Jessica Furrer) that brings together expertise and experience in process engineering, membrane science, microbial ecology, molecular biology, resource recovery, and water quality assessment to address some of the major challenges in making AnMBRs a feasible alternative to traditional aerobic wastewater treatment systems.

The project objectives are to (i) create innovations in membrane science and AnMBR process configurations to control membrane fouling, increase biogas production, and minimize the energy intensity of wastewater purification; (ii) analyze anaerobic soluble microbial products to assess membrane fouling potential and incorporate these findings into anti-fouling membrane design; and (iii) assess potable water quality and potential for energy and nutrient recovery from waste sludge. These objectives align very closely with two industry focus areas highlighted in the South Carolina Vision 2025: (i) energy and (ii) environment and sustainability.

Research Progress

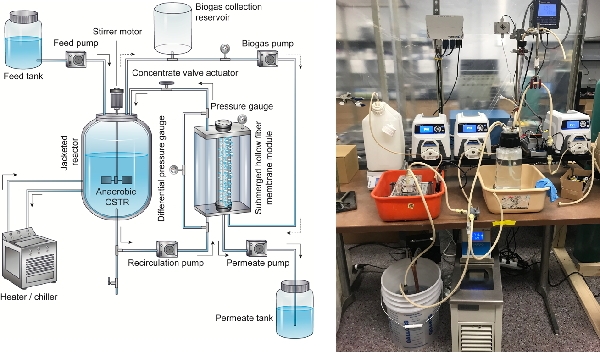

Our team is testing the feasibility of several novel research concepts to realize the potential of AnMBR treatment systems. The first key achievement was the construction of an AnMBR system to study methods for enhanced biological methane production and membrane fouling mitigation, both of which affect net energy production. We designed and built a fully automated AnMBR (Figure 2) that has operated continuously for more than 530 days treating a primary clarifier effluent from a local municipal wastewater treatment facility. We achieved continuous operation and maintenance of the AnMBR at three different temperatures, and obtained performance and microbial community data over the entire operational duration.

|

|

Figure 2. Schematic (left) and actual (right) AnMBR setup. |

A critical milestone was the production of methane, which requires a stable wastewater feed and well-controlled process parameters (e.g. temperature and absence of oxygen). Using the AnMBR setup, we have been measuring methane production rate and effluent water constituents, particularly high levels of recoverable phosphate and ammonium ions. A key goal with municipal wastewater treatment is COD (chemical oxygen demand) removal. Our AnMBR removes >80% of COD and produces 0.17 kWh/m3 of energy in the form of methane.

Another key research achievement has been assessment of different membrane configurations in the AnMBR. An important feature of our system is that the membrane cell is external to the bioreactor, which allows us to perform experiments with different membrane configurations and well-defined hydrodynamics. We have tested flat-sheet, tubular, and hollow fiber membrane configurations and found that the increased surface area of the hollow fiber configuration allows for higher organic loading and lower hydraulic retention times.

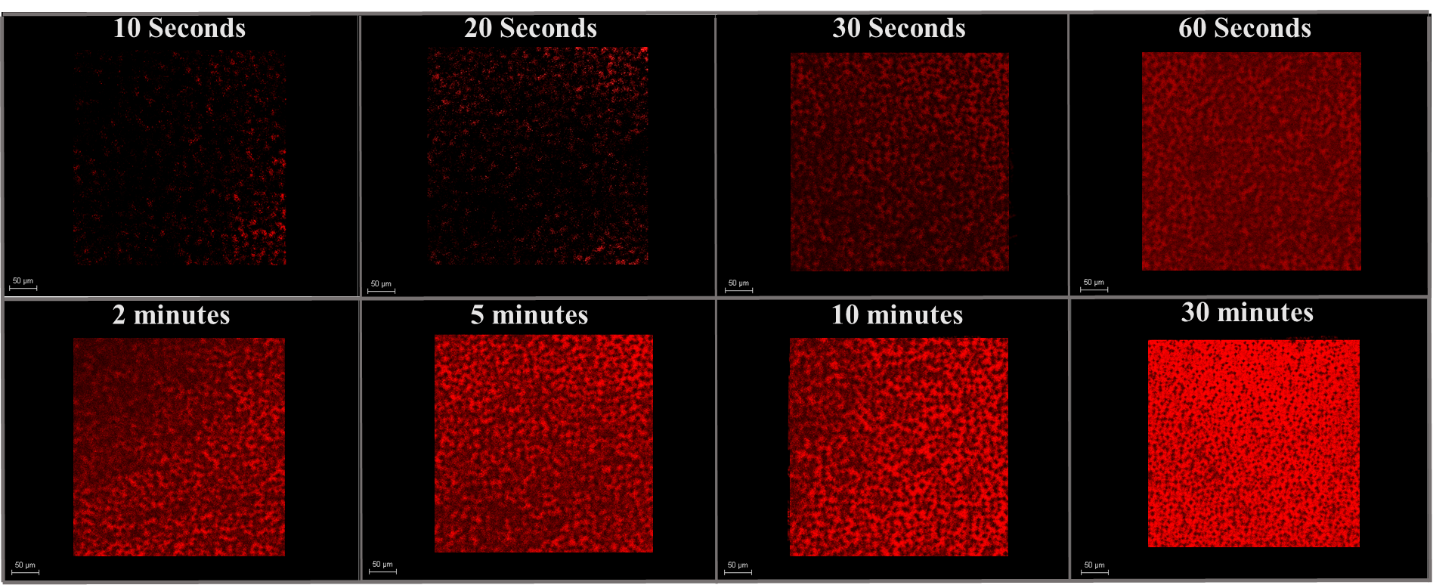

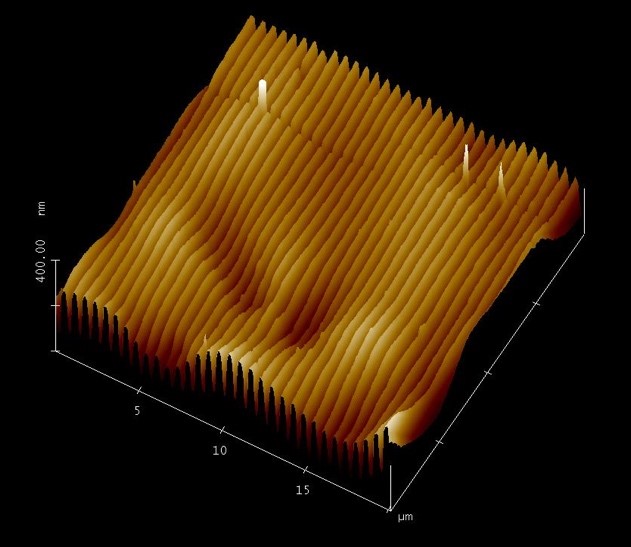

Using a combined experimental and computational approach, we are fabricating and testing new membranes with ordered surface patterns to understand the role of patterning on membrane fouling, which is a major challenge for energy-efficient operation. Experimental efforts have combined flux decline measurements with visualization by confocal laser scanning microscopy to study the fouling of as-received and patterned membranes during ultrafiltration of a model protein foulant. Figure 3 shows the fouling profile images at different filtration times on patterned and as-received membranes (presented as compilations of lateral x–y images taken at depth increments of 1.23 μm from the membrane surface (Z =0) to the bottom of the pattern). Comparing quantitative visual analysis of CLSM images with flux decline measurements is providing a better understanding of the causes of membrane fouling and the effect of patterning on the location and extent of fouling. Such knowledge is informing the design of membranes with features that prevent or direct the selective deposition of foulants in prone to foul regions.

|

|

Figure 3. Fouling profile images of BSA at eight filtration times on the surface of a patterned membrane (top images) and an as-received membrane (bottom images). Scale bar is 50 μm. |

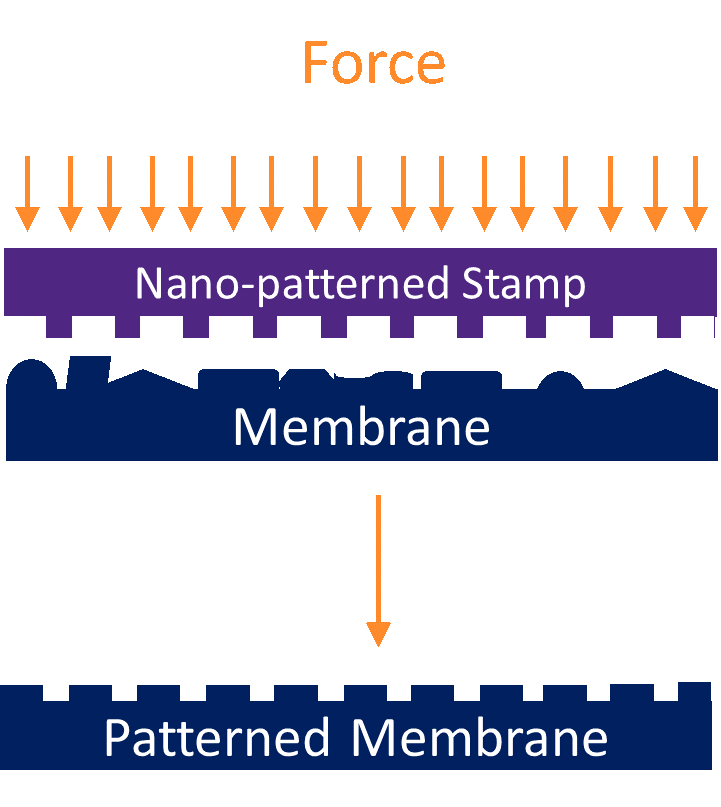

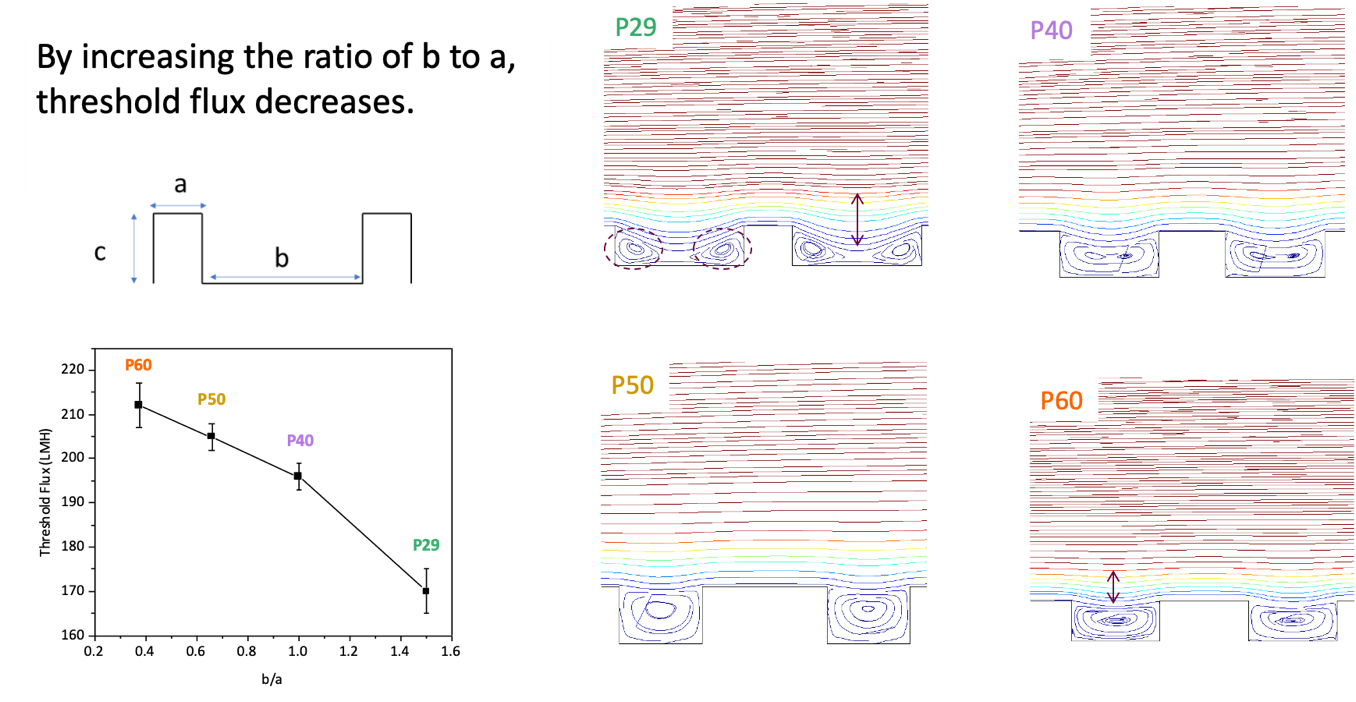

Our computational efforts involve the development of computational fluid dynamics models to aid the design of patterned membranes and membrane configurations. We are systematically evaluating how pattern dimensions influence threshold flux, which is an indicator of fouling propensity. Higher threshold flux indicates better fouling resistance. Figure 4 shows the embossing method used to pattern membranes with line and groove features. Figure 5 illustrates the effect of pattern dimensions on threshold flux and the results of CFD modeling. CFD results indicate the creation of local vortices. For small particles and proteins, moving from bulk to vortex streams is difficult, resulting in a reduction of deposited particles inside the recessions. However, when bulk streamlines penetrate the recessions, then particles are more likely to be trapped. The CFD models are thus helping to explain the trends observed for different pattern dimensions.

|

|

|

Figure 4-A. Illustration of embossing metho. |

Figure 4-B. Representative patterned membrane. |

|

|

Figure 5. Effect of pattern dimensions on threshold flux and corresponding CFD model results. |

Finally, we are studying the potential for hydrothermal carbonization (HTC) of biosolids from the anaerobic membrane bioreactor to generate a solid energy source or to be used to recover nutrients from these biosolids. We have discovered that that using HTC to create a solid energy source from these biosolids is not viable because of the low solids content in the solids stream. However, dewatering of these solids to achieve greater solids concentrations may result in greater recovery of solids and possibly a viable energy source. Nutrient recovery from process water generated during HTC using zeolite indicates that up to 95% and 85% of the ammonia and phsophrous, respectively, found in the process can be recovered and subsequently used as a fertilizer. We also have demonstrated that HTC is a suitable treatment option for elimination of DNA. Measurements indicate that DNA is below the limit of detection in carbonization products at typical carbonization temperatures. Thus, hydrochar products can be utilized without concern of spreading bacteria and antibiotic resistance genes to the environment.

Significance and Future Plans

Municipal wastewater treatment technologies based on aerobic processes are energy intensive, accounting for roughly 3% of the total US energy consumption and roughly 35% of the total energy consumed by municipalities. These treatment facilities produce large volumes biosolids that need to be digested, and fail to either utilize the energy embedded in waste organics or to recover valuable nutrients for beneficial reuse. Anaerobic processes, and particularly AnMBRs, offer a more sustainable approach. This EPSCoR/IDeA SRP project is laying the foundation for this new disruptive waste treatment technology with potential for near-term implementation. The project also is contributing to workforce development objectives by providing research training opportunities for a number of Ph.D. and B.S. students at four academic institutions.

Long-term plans for sustainability of the research effort and growth of the team include the submission of multi-investigator, multi-institution research and education proposals. Among them are funding opportunities aimed at translating the technology from bench- to commercial-scale operations.

August 2020